Factory Tour

An “Eel bedding” like factory with a depth that is unique to castle towns

Miso / Soy Sauce Factory building was build as a customer reception during the end of the Taisho era. It was renovated to the Miso / Soy Sauce Factory in 1989.

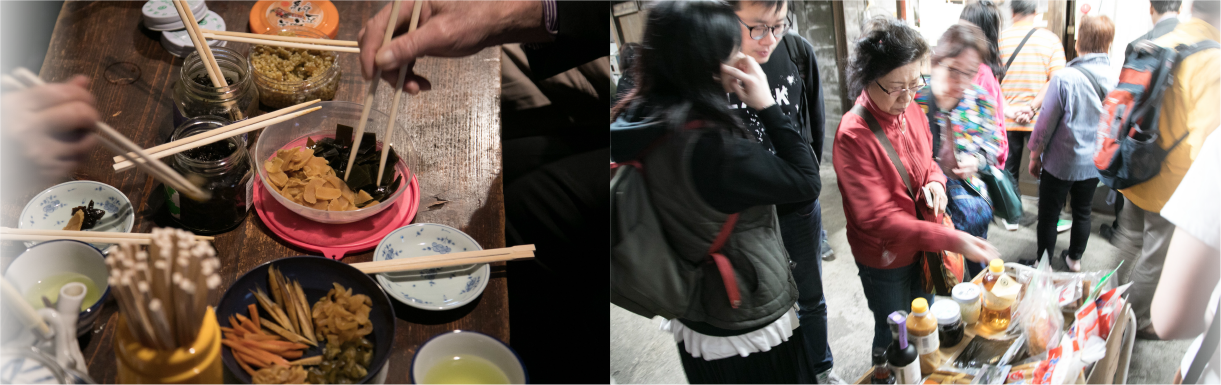

You can enjoy the quaint atmosphere of a factory from the past free. Tea and sampling of pickles and tsukudani are available.

Please enjoy the Taisho Romanticism era architecture.

Enjoy a free factory tour

Five points for enjoying the Factory Tour

Homemade Natural Moromi

Our commitment to age it for over one year

We are the only factory in the region manufacturing “Natural Moromi” fermenting using only soy, wheat and salt.

We age it over a period of over a year. The photography is the tank filled with moromi and the surface of the moromi.

Hitoyoshi and Tama Hinamatsuri (Doll’s Festival)

Heirloom Festival Dolls of the Kamada Family

From February to March, Hina Dolls are exhibited everywhere in Hitoyoshi City. The heirloom Hina Dolls of the Kamada family are exhibited at the Miso / Soy Sauce Factory during the “Hinamatsuri” period.

You can relax after the tour

After the tour, we have prepared green tea and product sampling.

In addition, our products are on display and available for purchase in the shop so please feel free to take the opportunity.

| Visiting Time | From 9:00am to 4:00pm |

|---|---|

| About Reservation | Please make a reservation in advance for groups of more than 10 people. Please make your reservation via phone or email.  Tel +81-966-22-3164 Tel +81-966-22-3164 Mail info@marukama.co.jp Mail info@marukama.co.jp

|

| Admission Fee | Free |

| Parking Area | Free (The parking area is also available for use for group buses.) |

| About Holidays | We are closed during year-end, New Year and public holidays so please check with us to make sure. |

1We head into the factory

-

Moromi Room

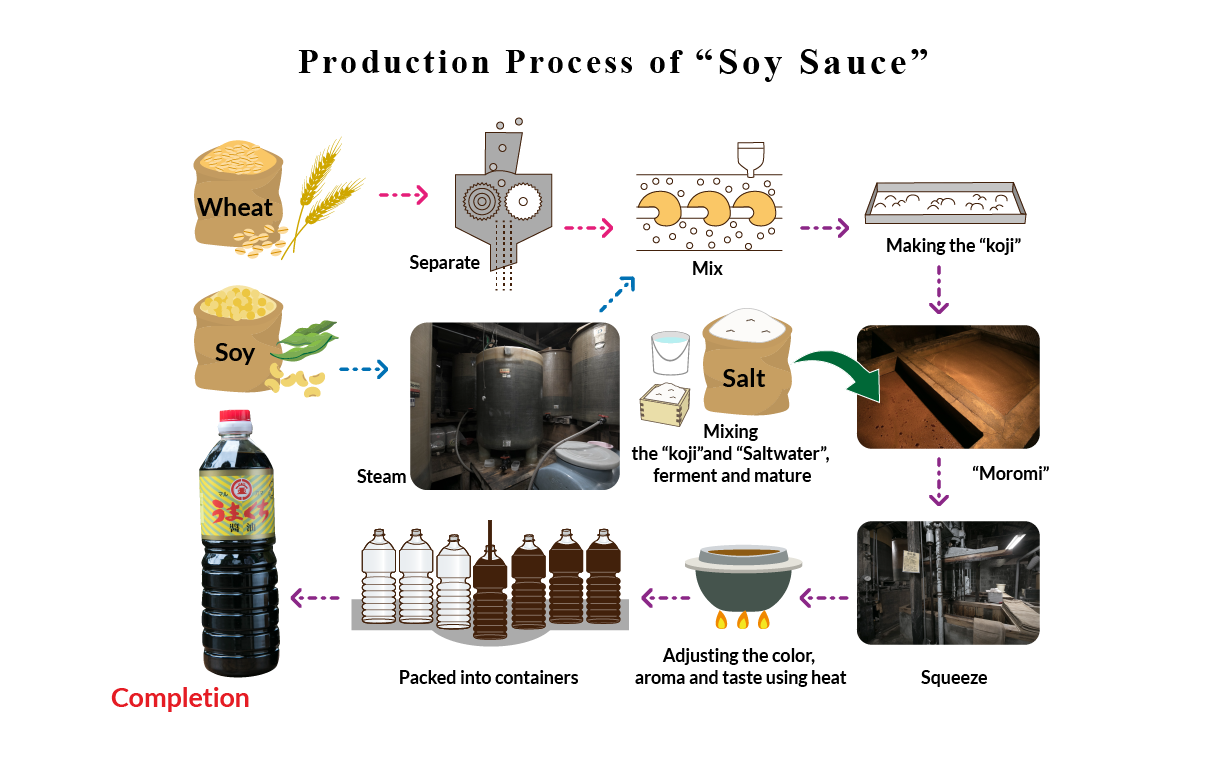

Steamed soy and roasted wheat are added with mixed koji seed to create “Soy Sauce Koji.”

This put together with saltwater creates moromi “fermented mash.”

Each tank can prepare up to 5,400 liters.

Our company’s moromi is aged in a natural environment with repeated stirrings for a year.

The koji mold, yeast and lactic acid bacteria will work on decomposing / fermenting, as the aging progresses, the soy sauce’s unique color, taste and aroma is born.

What we get from squeezing this is raw soy sauce (Namaage). -

Hydraulic Machine

This is a machine that squeezes soy sauce.

The moromi that has been aged for a year are put in a hemp bag and arranged at the bottom of the boat.

It will be left as is for a day and from the next day it will be pressurized for 3 days.

The pressure can take up to 150 tons. We call the freshly squeezed soy sauce Nama Shoyu (Raw Soy Sauce). The process is complete after further heating.

The flavor is also adjusted during the heating process.

The kasu that was squeezed dry is can also used as a nutrient rich cattle feed.

-

Bottling Operation

The finished soy sauce is then poured into a tank.

The tank is made from a glass fiber known as FRP, so that the line of the soy sauce that is poured in is clearly visible.

In addition, a hose connects from the tank to the bottling room. In this room, it will be packed into various containers, such as the 1 liter bottles, PET bottles, soy sauce bottles, even 9 liter for business use barrels.

Also, since the 1 liter bottles are recyclable bottles, it is collected and washed in the machine at the front and used.

Our factory also uses this soy sauce to manufacture tsukudani and pickles.

Particularly, the “Tsukudani with jelly ear mushroom and seaweed” is the most popular speciality.

Sampling will be available later at the factory, please look forward to it. -

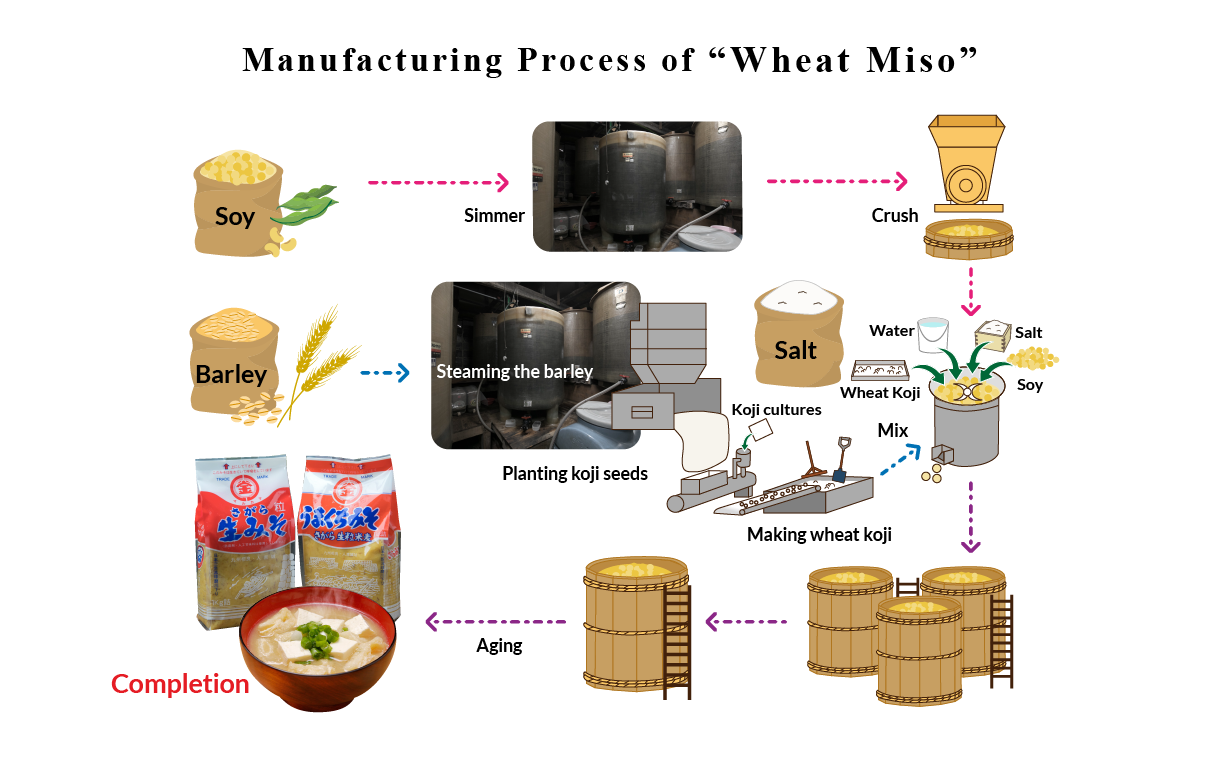

Koji Room / Steam Boiler

The koji room is where we make the koji, which is the source of miso and soy sauce.

There is soy and wheat soy sauce koji, barley and rice miso koji.

The process completes in 3 days at the temperature of about 30 degrees.

The steam boiler is a rotary pressure cooker that boils raw ingredients. For soybeans, it can boil up to 500 kg at one time.

You can perform washing, steaming and cooling the ingredients operations inside here.

3After the tour, you can sample the food at the sales exhibition area!

After the factory tour, we shall proceed to the sales exhibition area. Where you can purchase the products made by the manufacturing process you have just experienced.

Sampling of tsukudani and pickles are also available. We have tea prepared, so take your time to taste and compare.

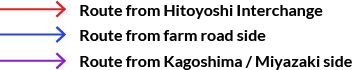

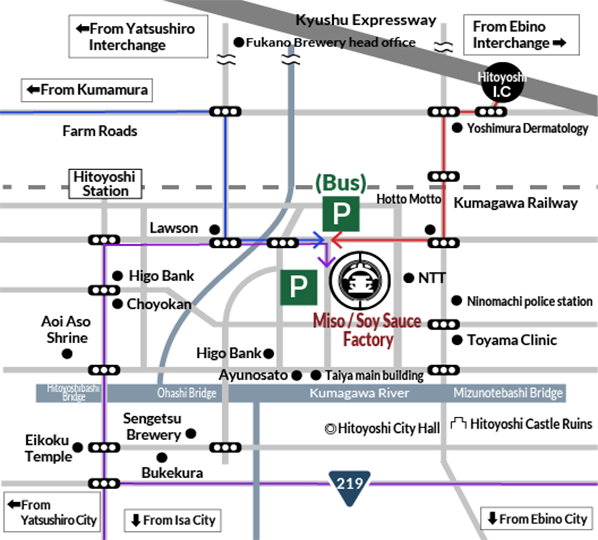

5 minutes by car from the Hitoyoshi Interchange

Parking for large buses are available.

Using the highway is recommended. Please feel free to visit us by car as we have ample parking lots available.

Benefits of Miso

Go to Access page

Go to Access page

Main entrance

Taisho Romanticism Architectural Style

Our company offers products that make full use of clean stream of Kumagawa River. Your can observe the manufacturing process right in front of you at the 100 meter deep elongated factory. After the tour, you can sample our tsudani and pickles that we are very proud of.